Tortoise tooth/hook tooth H

Belongs to the series:

1, oil quenching and continuous tempering technology, to maximize the hardness of the tooth tip and the toughness of the back material;

2. The unique heat treatment technology solves the knife bend and S bend of the saw blade, and improves the stability of sawing and sawing efficiency;

3. The fine grinding technology between the teeth improves the equal height, sharpness and smoothness of the tooth tip compared with the traditional tooth milling process, improves the wear resistance of the tooth tip, and is conducive to the smooth chip removal of the tooth groove;

4. Precision tooth division technology improves the smoothness and geometric tolerance of sawing;

5. The unique design of tooth edge and tooth profile angle is more suitable for sawing of different metal materials.

Higher tooth tip hardness and wear resistance than traditional bimetal band saw blades, as well as better saw back strength and fatigue resistance

|

Tooth tip hardness |

Tooth tip wear resistance |

Saw back performance |

Remarks |

|

|

Traditional products |

67 ≤ HRC≤ 68 |

General |

General |

Simultaneous heat treatment of serrated and sawback |

|

Company Products |

68 ≤ HRC≤ 69 |

Excellent |

Excellent |

Separate heat treatment of sawtooth and saw back |

The traditional bimetal band saw blade adopts the tooth shape processing method, and our company adopts the grinding tooth shape processing method, which makes the tooth groove surface more smooth, the tooth tip more sharp, and greatly improves the cutting performance of the saw blade.

|

Tooth tip edge degree |

cogging surface finish |

Sawing performance |

Remarks |

|

|

Traditional products |

General |

General |

General |

gear milling |

|

Company Products |

Excellent |

Excellent |

Excellent |

grinding teeth |

Product accessories

The company's main products are guide rail type CNC heavy-duty high-speed metal circular saw machine, supporting automation auxiliary machine, steel mill intelligent automation equipment, business also includes software development and related technical advice. The company has established a complete set of quality management, standardization and safety production management system, has passed the national ISO9001 quality management system certification, and is the governing unit of China Forging Association.

Customer Visits

For a long time, Junji people have been adhering to the business philosophy of taking the market as the center, meeting customer requirements to the maximum extent, "creating brands with heart and gaining credibility with sincerity", providing customers with high-quality products and services with rigorous and professional military quality and excellence, It has won unanimous praise in China Aerospace, China weapons, China Railway, automobile manufacturing, construction machinery, non-ferrous metal titanium alloy and other industries.

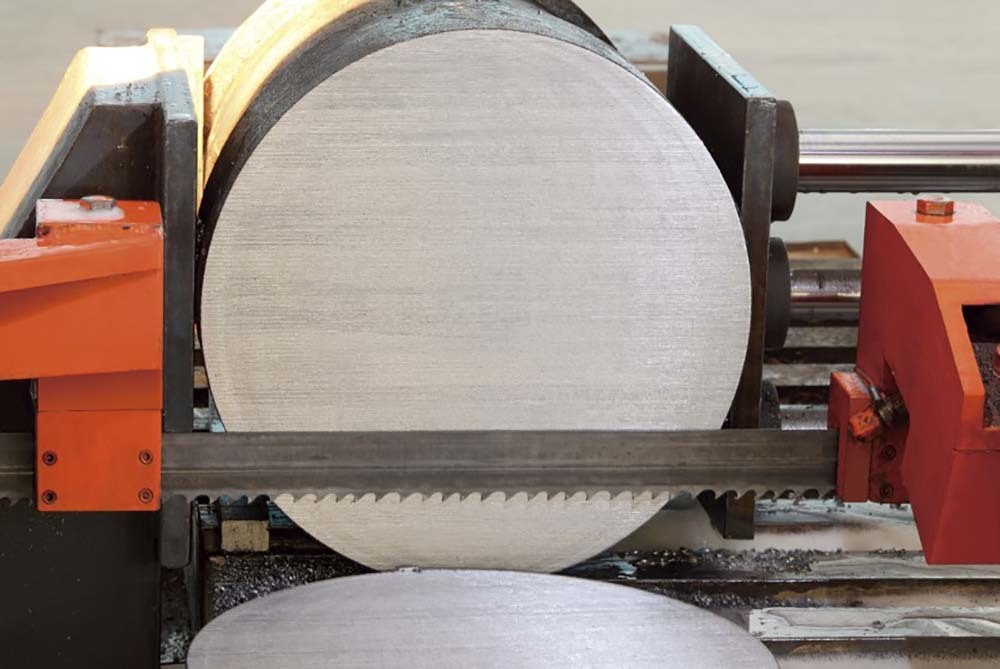

Operational Scenarios

At a new historical starting point, Junji Intelligence will, as always, provide better products, equipment and services to go hand in hand with new and old friends to create resplendence.

Case Presentation

The company's main products are guide rail type CNC heavy-duty high-speed metal circular saw machine, supporting automation auxiliary machine, steel mill intelligent automation equipment, business also includes software development and related technical advice. The company has established a complete set of quality management, standardization and safety production management system, has passed the national ISO9001 quality management system certification, and is the governing unit of China Forging Association.

Bimetal sawing

Bimetal sawing

Module sawing

Module sawing

FAQ

1, found that the cutting length is shorter?

2, when cutting a knife, suddenly found that the cutting surface is no longer smooth how to return a responsibility?

3. When cutting materials, there will be left and right cutting. What is the reason?

4. During normal cutting, abnormal feeding action occurs, such as sudden length of material head, such as non-action of feeding rack, etc. What is the reason?

5. The cylinder is not moving?

6. When cutting pipe materials, what is the abnormal noise during cutting?

Related Products

Product Consulting

PRODUCT INQUIRY

If you need our products, please fill in the relevant information on this page and submit it. There will be staff to contact you in time, or please call us directly.

Service Hotline:

Hotline:

Ms. Li, manager:008615689739177

Mr. Wang, manager:008615820092489

Address: Yuan Zhuang Industrial Park, Xianggong Zhuang Street, Zhangqiu District, Jinan City, Shandong Province